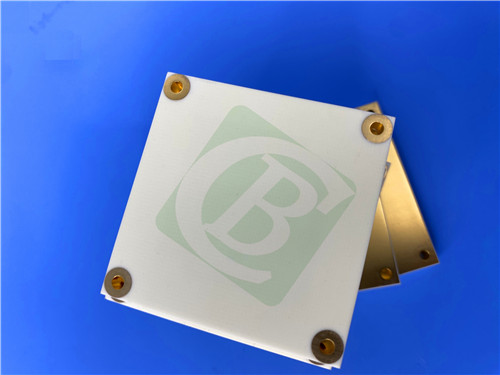

RO4003C 4-Layer 1.8mm Thick PCB with ENIG Finish and Blind Vias

1.Introduction

Rogers RO4003C materials are proprietary woven glass-reinforced hydrocarbon/ceramic laminates that combine the electrical performance of PTFE/woven glass with the manufacturability of epoxy/glass. These materials are ideal for high-frequency applications, offering tight control over dielectric constant (Dk) and low loss at a fraction of the cost of conventional microwave laminates. Unlike PTFE-based materials, RO4003C requires no special through-hole treatments, making it easier to process like standard FR-4 while delivering superior RF performance.

With a thermal coefficient of expansion (CTE) closely matched to copper, RO4003C ensures excellent dimensional stability, critical for mixed dielectric multi-layer boards. Its low Z-axis CTE enhances plated through-hole reliability, even under severe thermal shock conditions. The material’s high Tg (>280°C) guarantees stability across all circuit processing temperatures.

2.Key Performance Features

Dielectric Constant (Dk): 3.38 ±0.05 at 10GHz

Dissipation Factor (Df): 0.0027 at 10GHz, 0.0021 at 2.5GHz

Thermal Conductivity: 0.71 W/m/°K

CTE: X: 11 ppm/°C, Y: 14 ppm/°C, Z: 46 ppm/°C

Low Moisture Absorption: 0.06%

Thermal Stability: Tg >280°C (536°F)

Benefits

Ideal for multi-layer RF/microwave designs

Cost-effective fabrication (FR-4 compatible processes

Reliable performance in high-volume applications

3.PCB Specifications at a Glance

| Parameter | Specification |

|---|---|

| Base Material | RO4003C / RO4450F |

| Layer Count | 3 Layers |

| Board Dimensions | 291mm x 155mm (2 types, 2 pieces) ±0.15mm |

| Min Trace/Space | 5/4 mils |

| Min Hole Size | 0.3mm |

| Blind Vias | Top Layer to Inner Layer 1 |

| Finished Thickness | 1.82mm |

| Copper Weight (Outer/Inner) | 1oz (35µm) / 1oz (35µm) |

| Via Plating Thickness | 20µm |

| Surface Finish | Immersion Gold (ENIG) |

| Top Silkscreen | White |

| Bottom Silkscreen | None |

| Top Solder Mask | Black |

| Bottom Solder Mask | None |

| Electrical Test | 100% tested prior to shipment |

4.PCB Stackup: 3-layer rigid PCB

| Layer | Material | Thickness |

|---|---|---|

| Copper Layer 1 (Top) | Copper | 35 μm |

| Core 1 | Rogers 4003C | 0.813 mm (32 mil) |

| Copper Layer 2 | Copper | 35 μm |

| Bonding Ply | RO4450F | 0.102 mm (4 mil) |

| Core 2 | Rogers 4003C | 0.813 mm (32 mil) |

| Copper Layer 3 (Bottom) | Copper | 35 μm |

5.PCB Statistics:

Components: 32

Total Pads: 141

Thru Hole Pads: 73

Top SMT Pads: 68

Bottom SMT Pads: 0

Vias: 37

Nets: 5

6.Typical Applications

Cellular Base Station Antennas

RF Identification Tags

Automotive Radar/Sensors

Satellite LNB Circuits

7.Quality Assurance

IPC-Class 2 compliant

100% electrical tested

Global availability

Gerber RS-274X support